|

|

| Vintage and Classic Roadster Kit Car Builds For Vintage and Classic era kit cars. Post your build reports, problems and progress here |

9th August 2021, 22:15

|

|

Senior Member

|

|

Join Date: Jun 2015

Posts: 1,401

|

|

Perfect!

|

18th August 2021, 17:37

|

|

Senior Member

Enthusiast

|

|

Join Date: Sep 2004

Posts: 1,895

|

|

Made some good progress in the last couple of weeks. After a lot of fitting and refitting the rear body tub now fits square. It had been originally fitted (by Marlin) not very well and I had to fill all the original mounting holes and redrill them. Also, as it had not been square for some 40 years, the moulding had become a bit distorted and it resisted my efforts to sort it out. Fits fine now though!

tub_fitted1 tub_fitted1 by Robin Martin, on Flickr

Originally countersunk head screws were used for the fixings but these were perilously close to the edge so I have replaced them with conventional allen screws and large washers. Hopefully the wheel should hide most of them.

I was going to get some new leaf springs made but this was starting to look expensive so I thought I would check the originals a bit more closely. They turned out to be far better than I expected with little or no age related sag. Not bad seeing they are nigh on 50 years old. Picture shows them compared to a NOS original spring.

rear_springs rear_springs by Robin Martin, on Flickr

I was also able, to my suprise, to obtain new metalastic bushes. I suspect this is because they may be the same size as used in 1970's Fords. There isn't a lot of Marina bits out there. Burnt the old bushes out and the new ones pressed in suprisingly easily.

Rear_spring_bush Rear_spring_bush by Robin Martin, on Flickr

That's all for now and probably for a while. New kitchen fitting starts in ernest soon...

Cheers, Robin

|

1st September 2021, 09:10

|

|

Senior Member

Enthusiast

|

|

Join Date: Sep 2004

Posts: 1,895

|

|

The fuel tank, made by CompBrake, arrived and is exactly as my fag packet sketch so thumbs up to them. It fits almost perfectly (see below!) between the chassis rails as planned. The original tank was suspended much lower which made it rather vulnerable IMHO. The new tank is made from 3mm aluminium and so should be tough as old boots. It's also baffled and sumped so there shouldn't be any problems with fuel surge.

So - it fitted perfectly - almost... I discovered after a trial fit that the original tank mounting flanges on the chassis are positioned in such a way the the back of the tank is angled downwards by about an inch. Doh! No idea why but as the fuel take off on my tank is at the front this could prove to be a problem. Also I planned to use the tank top face as a level for the boot floor. Had I realised I could have had the flanges on the tank mounted at an angle to compensate but too late now. So i am going to have to grind off the flanges on the chassis and remake them so the tank is level. Grrrrrrrr......

Cheers, Robin

tank1 tank1 by Robin Martin, on Flickr

tank3 tank3 by Robin Martin, on Flickr

|

10th September 2021, 16:41

|

|

Senior Member

Enthusiast

|

|

Join Date: Sep 2004

Posts: 1,895

|

|

Today I bit the bullet and chopped the old, very rusty, spring pads off the axle and replaced them with new shiny ones.

My main concern was getting the new ones back in exactly the right place. To position them laterally I marked the axle with the ends of original spring pads with a centre punch. I then cut of the first mount. The axle was extremly rusty due to the design of the spring pads allowing water to collect - I hope the strength hasn't been compromised.

axle1 axle1 by Robin Martin, on Flickr

I then levelled up the new pad by axle using a spirit level on the remaining pad and then again on the new pad.

axle2 axle2 by Robin Martin, on Flickr

And then welded the new pad in place. The process was repeated for the other pad.

axle4 axle4 by Robin Martin, on Flickr

Ok - so my welding won't win any prizes but its strong enough...

And finally, cleaned up the brake back plates which were in suprisingly good condition considering they are 50 years old! The shiny bits in the picture are good clean bare metal.

axle6 axle6 by Robin Martin, on Flickr

Just needs a coat or two of paint now....

Cheers, Robin

|

10th September 2021, 16:57

|

|

Senior Member

|

|

Join Date: Jun 2015

Posts: 1,401

|

|

looking good Robin

|

11th September 2021, 11:28

|

|

Senior Member

Enthusiast

|

|

Join Date: Mar 2005

Posts: 3,079

|

|

Nice welding, much better than mine, well done

|

21st September 2021, 12:16

|

|

Senior Member

Enthusiast

|

|

Join Date: Sep 2004

Posts: 1,895

|

|

A little bit of progress mainly due to the fact that IKEA seem to be out of stock of some of the components for our new kitchen! Which seems to prevent you ordering any of it....

So - I trial fitted the rear springs and all the bits that the axle hangs on. Bit of a milestone this as it means I am actually starting to assemble the car rather than dismantle!

Not quite as simple as it would first appear as the original U-Bolts and lowering block were shot so I had to get some replacements. Of course Marina ones are simply not available so in the end I used some Grayston lowering blocks and U-bolts intended for the Ford Escort. Actually better quality than I expected. I had to squish the u-bolts slightly as they were a few mm wider than the original ones. But they are made properly from HT steel, it seems, so I had to heat up the U bit to cherry red before they would move. They are also 1/16" greater in diameter so had to fettle the spring plates.

The other good game was the rubber spring pads. Again originals unavailable. You can get them from one of the polybush companies but they are over £100 for the 4! In the end I modified some intended for an MGB. Cost me all of £6.

axle5 axle5 by Robin Martin, on Flickr

Cheers, Robin

PS - The block of wood is the axle simulator...

|

12th October 2021, 10:07

|

|

Senior Member

Enthusiast

|

|

Join Date: Sep 2004

Posts: 1,895

|

|

I trial fitted the refurbished axle this weekend. It is very heavy! I have been pontificating about what dampers to use but Ebay had a special offer on Spax adjustables (20% off) so I spashed the cash and bought both rears and fronts (which are actually Herald rears).

axle trial fit axle trial fit by Robin Martin, on Flickr

The only real issue I had, prior to fitting, was the handbrake compensator lever which mounted using some long ago perished rubber top hat bushes. I managed to find an oilite bush of almost the correct size which was a tight press fit and used that instead. Probably better than the original.

hand brake compensator hand brake compensator by Robin Martin, on Flickr

The only snag, and yet to be resolvled, is the proximity of the handbrake cables to the damper. I think it could well touch when the car is moving. Which probably wouldnt really matter but I guess it would be an MOT failure....

hand brake cable hand brake cable by Robin Martin, on Flickr

Next job is to remake the rear bulkhead - which I am going to make in steel rather than the original ally. That's going to be fun - folding 1.2mm zintec. Watch this space...

Cheers, Robin

|

13th October 2021, 17:06

|

|

Senior Member

Enthusiast

|

|

Join Date: Sep 2004

Posts: 1,895

|

|

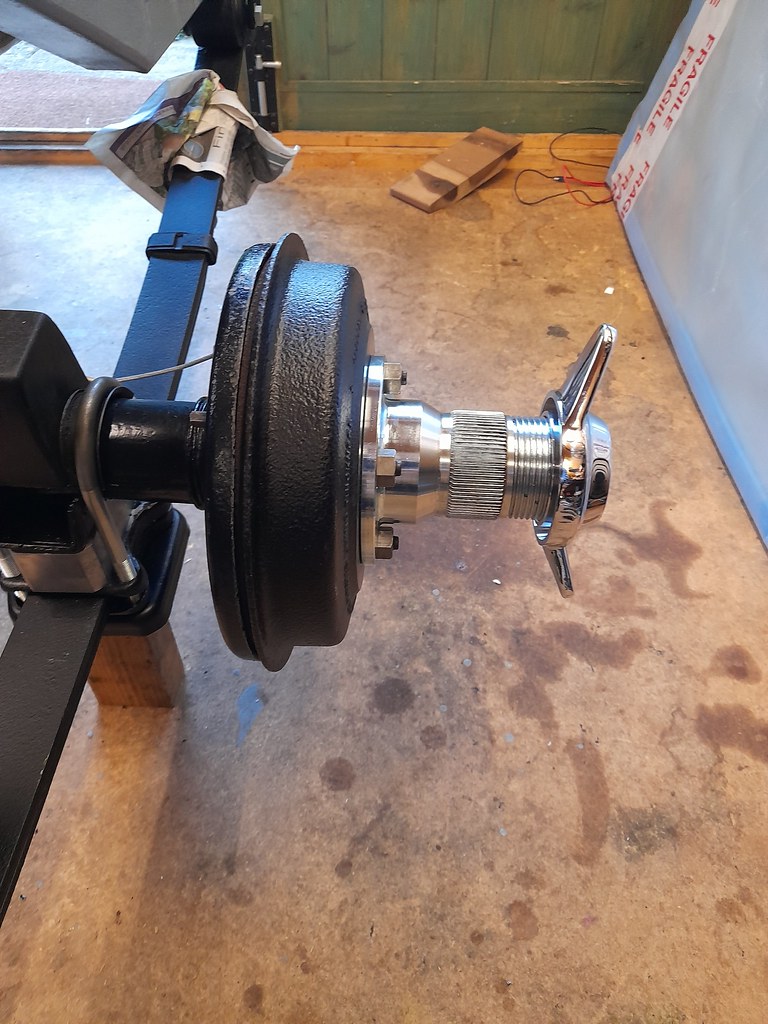

Couldn't resist trying a splined hub and wire wheel. The hubs were intended for one of the small Triumphs, but as these share a lot of parts with the Marina I gambled they would fit.

They look awfully wide until you fit a wheel at which point - they look perfect IMHO...

Cheers, Robin

splined_hub splined_hub by Robin Martin, on Flickr

wire_wheel wire_wheel by Robin Martin, on Flickr |

13th October 2021, 17:39

|

|

Senior Member

|

|

Join Date: Jun 2015

Posts: 1,401

|

|

Looks good!

|

14th October 2021, 14:14

|

|

Junior Member

|

|

Join Date: Feb 2012

Posts: 18

|

|

Hi Robin

I love the look of wires on the Roadster.

When I originally built my roadster back in 1986 I fitted adaptors and wires like you.

WARNING: Make sure the wire wheel seats correctly onto the tapered part of the adapter. I had loads of problems with mine until I realised the wheels were seating onto the top of the wheel studs. After grinding them back flush with the wheel nuts I managed to get them to work correctly. Hope this makes sense.

Jon

|

14th October 2021, 16:37

|

|

Senior Member

|

|

Join Date: Aug 2012

Posts: 2,143

|

|

Good tip ! I usually put a blob of paint onto each wheel stud and fit the wheel. Remove it again and check for paint on the back of the wheel.

|

21st October 2021, 12:13

|

|

Senior Member

Enthusiast

|

|

Join Date: Sep 2004

Posts: 1,895

|

|

Thanks for the comments and tips. STILL waiting for my Ikea kitchen so progress continues. After a lot of delays the zintec steel for my front and rear bulkheads arrived. I am making them from steel as opposed to the original alluminium for strength. The front bulkhead tends to crack arround the pedal box and the rear bulkhead has the seatbelts mounted to it. I was able to use my newly beefed up bender for the first time. As expected the folds are fairly soft but fine for the purpose.

on_a_bender on_a_bender by Robin Martin, on Flickr

rear_bulkhead2 rear_bulkhead2 by Robin Martin, on Flickr

It fits considerably better than the original factory made effort - even if I do say so myself!

Cheers, Robin |

21st October 2021, 12:46

|

|

Senior Member

|

|

Join Date: Jun 2015

Posts: 1,401

|

|

nice work!

|

21st October 2021, 15:07

|

|

Member

|

|

Join Date: Feb 2012

Posts: 38

|

|

Very neat job !

|

3rd November 2021, 09:36

|

|

Senior Member

Enthusiast

|

|

Join Date: Sep 2004

Posts: 1,895

|

|

Heater Options

Heater Options

I am currently re-making the front bulkhead of DRL152K and, as that is where it may be mounted, I am thinking about heater options. I wondered what others have done and I have a few questions.

Is it worth the effort fitting windscreen demisters? I will only very occasionally be using a hood.

Is it worth trying to get fresh air in, or is a simple recirculating heater the better (and simpler!) option.

And where is the best place to mount the heater? I was going to put it on top the bulkhead, as per the manual, but if I use one of the smaller aftermarket jobbies (T7 design is favourite) it's probably small enough to sit under the dashboard on top of the transmission tunnel.

Cheers, Robin

|

3rd November 2021, 10:37

|

|

Senior Member

|

|

Join Date: Jul 2011

Posts: 5,328

|

|

I had one of these in my Spyder -

https://www.t7design.co.uk/2-2kw-mic...9-cc4-d35.html

It never really put much heat out, I'm afraid, even taking into account that it was in a completely open car. I've gone for a much bigger heater matrix from a production car (VW Corrado) with a surface mount fan for my latest project, which is also going to be completely open.

As for fresh air inlet and demisting, the two really go hand in hand and I'd say they will be essential for safety reasons if you get caught in a downpour with the hood up. |

18th November 2021, 18:20

|

|

Senior Member

Enthusiast

|

|

Join Date: Sep 2004

Posts: 1,895

|

|

I have made some good progress on replacing the front bulkhead. The original was rather tired and had a scary crack from pressure from the pedal box.

cracked cracked by Robin Martin, on Flickr

I have made the replacement in steel, the same as the rear bulkhead. Proved to be quite tricky getting it right particularly at the bottom arround the chassis members. I have a couple of closing plates to still to fit there.

The pedal box is also trial fitted. I have made a L & H shaped reinforcement from 25mm angle to help spread the load. The clutch pedal needs a little adjustment using the blowtorch and hammer it seems.

The observant might notice there are 2 rows of fixings at the top rear of the bulkhead. The original design used the same fixings both to fix the scuttle (dashboard) moulding and secure the bulkhead to a chassis crossmember. I decided to make those seperate thereby improving the strength. I know the fixings are stainless, generally frowned upon for anything structural, but there are enough of them to well distribute any loads. On the final assembly I will also bond the bulkhead using a Sikaflex adhesive - same as I did on the Pembleton.

front_bulkhead1 front_bulkhead1 by Robin Martin, on Flickr

front_bulkhead2 front_bulkhead2 by Robin Martin, on Flickr

Next job: overhaul the steering rack and decide on the position for the steering column. I want it under, rather than through, the dash as in the original design. The orginal Marina steering column is pretty shot so I am thinking of using one from a Triumph Spitfire for which you can still get things like bushes.

Cheers for now, Robin

|

19th November 2021, 09:12

|

|

Senior Member

|

|

Join Date: Mar 2012

Posts: 1,152

|

|

Very neat, and it will bring greater peace of mind.

It inspires me to get back to my project.

|

19th November 2021, 10:57

|

|

Senior Member

Enthusiast

|

|

Join Date: Mar 2005

Posts: 3,079

|

|

Nice work Robin, as expected

Perhaps you should make a few more for other Marlin restorers? |

|

Currently Active Users Viewing This Thread: 190 (0 members and 190 guests)

|

|

|

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is Off

|

|

|

All times are GMT +0. The time now is 06:55.

|