|

|

| Vintage and Classic Roadster Kit Car Builds For Vintage and Classic era kit cars. Post your build reports, problems and progress here |

27th February 2021, 19:15

|

|

Senior Member

Enthusiast

|

|

Join Date: Mar 2005

Posts: 3,079

|

|

Belted up.............

Belted up.............

Thanks Amir and Mr. Towed.

--------------------------------------------------------

This week I've addressed a long standing issue that I've been aware off ever since I first got my Sabre.

As I said above, my car is a very early one manufactured in 1994, well before the SVA now replaced by the IVA test.

This is the diagram from the IVA manual that shows how to check the height of the upper anchorage point for the seat belts. The minimum height from the reference point 'R' is 450mm in the text. And as you can see the seat type and mounting height is also important.

IVA seatbelt height IVA seatbelt height by Sabrebuilder, on Flickr

This is the view of the Sabre's upper anchorage point as designed in 1994. The upright is welded to the chassis. The diagonal brace takes the seat belt upper mounting and the hood frame.

Hood frame and rear brace Hood frame and rear brace by Sabrebuilder, on Flickr

On later Sabre's the seat belt mounting point is welded into the top of the vertical 'B' post. The post is longer making this point higher and the post is mounted more inboard so the diagonal is flat and bolted to the outside edge of the post.

Photo courtesy of Stewart Arnott

Later Sabre chassis Later Sabre chassis by Sabrebuilder, on Flickr

I could have had the chassis reworked as this type of welding was way beyond my capability. Instead, I've raised the seatbelt mounting by welding a small plate to the diagonal and re-drilling the mounting hole in this plate. (The folding hood frame will need to be modified but that shouldn't be too difficult.) The plate is the same thickness as the original diagonal brace and I welded it on both sides to make it as strong as possible. In an accident, the weld will be mostly under compression.

I also plan to rework the interior trim so that it covers the diagonal upper edge.

Modified seatbelt diagonal Modified seatbelt diagonal by Sabrebuilder, on Flickr

The IVA examiners have a special measurement tool with string and spirit levels. I improvised with a piece of timber mounted between the seatbelts. The top surface of the timber is the 'effective anchorage point'.

Seatbelt height measurement Seatbelt height measurement by Sabrebuilder, on Flickr

I made up the IVA specified 'distance piece' from a cereal carton. The cross section is exactly 136mm x 53mm

IVA distance piece IVA distance piece by Sabrebuilder, on Flickr

I then clamped a steel rule to the timber and used my magnetic spirit level to make sure the steel rule was level.

Seatbelt height measurement Seatbelt height measurement by Sabrebuilder, on Flickr

I could then measure from the reference point to the horizontal steel rule.

Seatbelt height measurement Seatbelt height measurement by Sabrebuilder, on Flickr

Seatbelt height measurement Seatbelt height measurement by Sabrebuilder, on Flickr

My measurement comes out at 468mm so hopefully I have about 18mm 'contingency' for measurement error.

So, I think I've cracked this issue but if anyone can see a flaw in my solution please shout out as I'd rather know now than find out at the IVA test

....peter

|

28th February 2021, 09:59

|

|

Senior Member

|

|

Join Date: Feb 2012

Location: Wembley, London

Posts: 5,058

|

|

Peter - I assume the cardboard was set in position for the measurement?

(And just left laying flat in the photo.)

In which case, I think you have designed a way of matching the IVA measurement.

Not sure if I've posted this link before, or even if it covers seat belt mounting.

But it has a lot of practical demonstrations of the test and how to pass.

https://www.rodsnsods.co.uk/threads/...h-biva.405393/

Finally, the new welded plate is quite short (relative to the length of the original mounting bar).

So, I'd be tempted to bolt a cross brace bar between the two original pieces to form a triangle just in case.

(Assuming it wouldn't be in the way of any other fitting.)

Good luck, Paul.

|

2nd March 2021, 20:52

|

|

Senior Member

Enthusiast

|

|

Join Date: Mar 2005

Posts: 3,079

|

|

Quote:

Originally Posted by Paul L

Peter - I assume the cardboard was set in position for the measurement?

(And just left laying flat in the photo.)

............

I'd be tempted to bolt a cross brace bar between the two original pieces to form a triangle just in case.

(Assuming it wouldn't be in the way of any other fitting.)

Good luck, Paul.

|

Hi Paul,

many thanks for your feedback and the BIVA link. I haven't read the whole thread yet (25 pages!!) but the description of the IVA test and failure points are always good learning points.

The photo's have 'flattened' my spacer piece. It is actually a box with six sides that lifts the ruler off the seat by the required amount. It just looks flat in the photo's.

I also like your idea of a cross brace. I'm not sure it's needed but I think it will be relatively simple to add so I'll take a look next time I'm in the garage.

cheers, Peter |

6th March 2021, 19:24

|

|

Senior Member

Enthusiast

|

|

Join Date: Mar 2005

Posts: 3,079

|

|

Dash surround........

Dash surround........

I'm not finished with the seatbelt mountings, but happy that I now have a solution I have moved on to the Dashboard Surround.

This is something that I've been putting off for a long time whilst considering whether to leave it as it is or try and change it.

From a distance, the leather covered dash surround looked smart but close up it was poorly finished and starting to come loose.

Dash surround Dash surround by Sabrebuilder, on Flickr

But close up it didn't look so good.

This is an example of the finishing that could have been done neater, This is the passenger side top of the surround and was visible when the door was open.

Dash surround Dash surround by Sabrebuilder, on Flickr

Also, the preformed glovebox was badly fitted and the hole in the dashboard surround looks like it was done in a hurry and doesn't match the 'box.

Glovebox Glovebox by Sabrebuilder, on Flickr

Removing the leather cover was easy with just my fingers as the 25 year old evo-stick adhesive had gone brittle and crumbly. Of course, it then took me a few hours removing the old glue with adhesive cleaner.

This picture is the surround after I had cleaned it up and started filling the gaps around the glovebox.

Dash surround Dash surround by Sabrebuilder, on Flickr

I then sanded and smoothed the filler.

Glovebox Glovebox by Sabrebuilder, on Flickr

And gave it a coat of primer.......

Glovebox Glovebox by Sabrebuilder, on Flickr

I then checked what it looked like with the dash in place.....

Glovebox Glovebox by Sabrebuilder, on Flickr

It looks a lot better but needs a bit more filling and smoothing before I give it a coat of satin black.

More work planned on the surround next week............

........peter

.

|

22nd March 2021, 18:33

|

|

Senior Member

Enthusiast

|

|

Join Date: Mar 2005

Posts: 3,079

|

|

Skipping back a couple of weeks, Paul made this comment about my upper seatbelt mounting point..........

Quote:

Originally Posted by Paul L

Finally, the new welded plate is quite short (relative to the length of the original mounting bar).

So, I'd be tempted to bolt a cross brace bar between the two original pieces to form a triangle just in case.

(Assuming it wouldn't be in the way of any other fitting.)

Good luck, Paul.  |

I've had a look at Paul's suggestion but I don't think it would add much strength because the upright, diagonal and the chassis are already effectively

a large triangle.

However, it did prompt a new idea........

I've added a 6mm thick plate across the welded extension plate. This 'locks' in position the original diagonal to the upright support. This makes an extremely strong arrangement and the extra plate would stop the diagonal tearing away from the welded piece in an accident.

Seatbelt support Seatbelt support by Sabrebuilder, on Flickr

Here is a view of the upper seatbelt mount from above with the extra plate.

Seatbelt support Seatbelt support by Sabrebuilder, on Flickr

And for completeness, here's a photo of where the seatbelt diagonal is bolted to the chassis.

Seatbelt support Seatbelt support by Sabrebuilder, on Flickr

I'm now happy with this arrangement and I can cross this task of my list.

I'm now working on covering the dashboard surround and will post some pictures next week.

Stay safe..............peter

|

22nd March 2021, 19:27

|

|

Senior Member

|

|

Join Date: Oct 2013

Location: norfolk

Posts: 691

|

|

Just a small thought..... do you need to use dome head screws, or covers over the existing hex screws to make the IVA compliant?

|

27th March 2021, 10:53

|

|

Senior Member

Enthusiast

|

|

Join Date: Sep 2004

Posts: 1,895

|

|

Looking great. Upholstery is one of those things that I never achieved satisfactory results. I don't think I have the patience....

Cheers Robin

|

27th March 2021, 22:43

|

|

Senior Member

Enthusiast

|

|

Join Date: Feb 2005

Location: Hampshire

Posts: 2,497

|

|

Looking good  |

3rd April 2021, 19:29

|

|

Senior Member

Enthusiast

|

|

Join Date: Mar 2005

Posts: 3,079

|

|

Thanks for the feedback, Robin and Patrick.

----------------------------------------------------

This week I've finished covering the dashboard surround so I've PU glued the demister pipes back in again.

Demister pipe Demister pipe by Sabrebuilder, on Flickr

CORRECTION: THESE TUBES SHOULD HAVE BEEN FIXED AT 45 DEGREES. SEE POST #535 for the correct method.

And, I've made up these little adapters to connect the demist hoses to the Sierra heater box. I Araldited the tubes into the plywood bases before giving them a coat of black paint.

Demister heater adapters Demister heater adapters by Sabrebuilder, on Flickr

I'm planning on fitting my windscreen glass before re-fitting the dashboard surround as it's easier access to both sides and I don't want to get the windscreen adhesive on the dash surround.

Stay safe.................peter

Last edited by peterux; 31st July 2021 at 21:14..

Reason: correction to demister tube mounting

|

11th April 2021, 19:10

|

|

Senior Member

Enthusiast

|

|

Join Date: Mar 2005

Posts: 3,079

|

|

This week I've finished off the dashboard surround by fitting a new pair of chrome plated vents. Amazingly these are still available after 27 years!

Dashboard surround Dashboard surround by Sabrebuilder, on Flickr

I've pre-wired the aux power outlets and attached the demister hoses ready to be connected to the heater box.

Dashboard surround Dashboard surround by Sabrebuilder, on Flickr

I then remembered to fit the chrome side finishers. The rear fixing stud is very difficult to reach and see and would not be possible to reach with the dashboard surround in place.

Chrome finisher Chrome finisher by Sabrebuilder, on Flickr

The rear stud is fiendishly difficult to reach and should have been fitted before anything else. A lesson for any other builders following my re-build.

Chrome finisher Chrome finisher by Sabrebuilder, on Flickr

Stay safe...............peter. |

19th April 2021, 20:40

|

|

Senior Member

Enthusiast

|

|

Join Date: Mar 2005

Posts: 3,079

|

|

Windscreen recovery

Windscreen recovery

The original windscreen fitted to my Sabre was BSI marked but not E-43R marked as now required for the IVA test. I'd removed the old windscreen when I first stripped the car down and purchased a new 'E' marked from Automotive Creations back in 2013 or maybe 2014. But for some reason, which escapes me now, I had never trial fitted it in the car, that is until a coupe of wees back when I found it didn't fit.

I was dreading the thought of taking the laminated windscreen to the local glazers expecting to be greeted with the usual sucking through teeth and shaking of heads!

So I turned to YouTube for inspiration where I found lots of 'how to' video's. One guy in particular impressed me as he was cutting down curved laminated 'screens for American custom cars. He made it look so easy so I thought I'd give it a go.

I first armed myself with a new 'professional' glass cutter (Japanese Toyo TC17), a small bottle of cutting oil and a cheap pair of 'grozing' pliers. You also need a blow lamp to soften the plastic core of the laminated screen!

Windscreen Windscreen by Sabrebuilder, on Flickr

The oil goes inside the glass cutter and automatically feeds a small amount to the wheel.

I also bought the cheapest laminated windscreen I could find to practise on. It cost me less than £35 including delivery.

I had a few practise runs with quite a good result.

Windscreen Windscreen by Sabrebuilder, on Flickr

I then made a plywood template to fit the car so that I knew exactly what cuts to make. It turned out I needed to remove 8mm from the long edge and 4mm from the short edge. I was lucky that the curved side of the windscreen was fine. So I had another practise removing 8mm strip from my test 'screen.

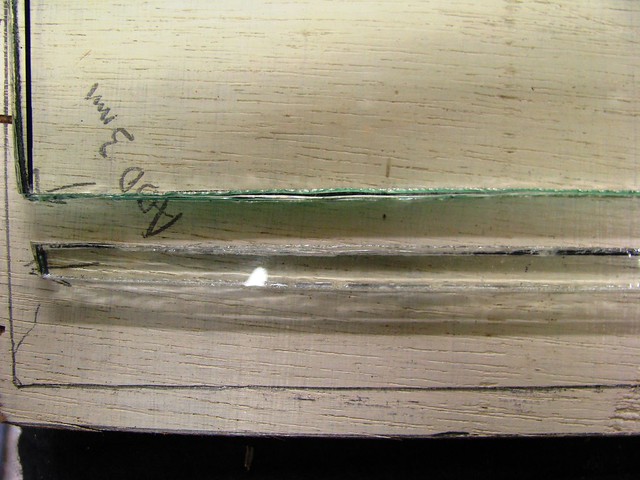

Windscreen Windscreen by Sabrebuilder, on Flickr

I then took a deep breath and had a go at the Sabre windscreen...

Windscreen Windscreen by Sabrebuilder, on Flickr

Success......

Windscreen Windscreen by Sabrebuilder, on Flickr

The edges were a bit rough so I bought one of these from Amazon...

Windscreen Windscreen by Sabrebuilder, on Flickr

Which gave a very acceptable finish........

Windscreen Windscreen by Sabrebuilder, on Flickr

Not bad for pure novice but I haven't had a go at cutting a curve yet

The other little job I've done this week is make and fit a tether for the fuel cap.

I used stainless steel picture wire and part of a bath plug chain.

(Another pesky IVA requrement).

Fuel tank cap tether Fuel tank cap tether by Sabrebuilder, on Flickr

Fuel tank cap tether Fuel tank cap tether by Sabrebuilder, on Flickr

Fuel tank cap tether Fuel tank cap tether by Sabrebuilder, on Flickr

Fuel tank cap tether Fuel tank cap tether by Sabrebuilder, on Flickr

So another couple of tasks crossed of my list..........

Stay safe, peter

|

19th April 2021, 21:02

|

|

Senior Member

|

|

Join Date: Jun 2015

Posts: 1,401

|

|

Very good info on laminated glass cutting. Another skill learned.

|

20th April 2021, 13:35

|

|

Senior Member

Enthusiast

|

|

Join Date: Mar 2005

Posts: 3,079

|

|

Quote:

Originally Posted by molleur

Very good info on laminated glass cutting. Another skill learned.

|

This is the guy that gave me the inspiration and the confidence to have a go but there are lots of other 'how to' videos available.

https://youtu.be/kTM8Xy4HYAI

He uses a bit of broken tape measure to cut through the plastic but I just used a single sided razor blade. |

20th April 2021, 15:04

|

|

Senior Member

|

|

Join Date: Oct 2013

Location: norfolk

Posts: 691

|

|

I witnessed a laminated screen being trimmed by a professional many years ago.

He scored each sheet of glass, and cracked it, then to deal with the laminate he dripped lighter fuel in the gap and ignited it.

|

20th April 2021, 19:56

|

|

Senior Member

Enthusiast

|

|

Join Date: Mar 2005

Posts: 3,079

|

|

Quote:

Originally Posted by Mitchelkitman

He scored each sheet of glass, and cracked it, then to deal with the laminate he dripped lighter fuel in the gap and ignited it.

|

Yes, there are even video's showing that technique on YouTube but I decided the blow lamp was a safer option.  |

20th April 2021, 15:01

|

|

Senior Member

|

|

Join Date: Jun 2015

Posts: 1,401

|

|

Your post had me very interested. Watched some videos and

it looks like a good method. Filed away for future reference.

Thanks, good info.

|

20th April 2021, 20:15

|

|

Senior Member

Enthusiast

|

|

Join Date: Feb 2005

Location: Hampshire

Posts: 2,497

|

|

Nice work!

|

22nd April 2021, 07:35

|

|

Senior Member

Enthusiast

|

|

Join Date: Sep 2004

Posts: 1,895

|

|

I have a remark about your "sunken" fuel filler. I don't know if it may be an IVA issue but possibly worth checking.

Is there anything in place to drain away any splashes or fuel spillage? Normally with an external filler it would just run down your nice clean bodywork, but with a sunken filler where does it go?

When race and rally cars have an internal filler like that it is normally surrounded by a splash bowl. Or so I beleive looking at various pictures :-)

Cheers, Robin

|

22nd April 2021, 19:32

|

|

Senior Member

Enthusiast

|

|

Join Date: Mar 2005

Posts: 3,079

|

|

Quote:

Originally Posted by MartinClan

I have a remark about your "sunken" fuel filler. I don't know if it may be an IVA issue but possibly worth checking.

Is there anything in place to drain away any splashes or fuel spillage? Normally with an external filler it would just run down your nice clean bodywork, but with a sunken filler where does it go?

When race and rally cars have an internal filler like that it is normally surrounded by a splash bowl. Or so I beleive looking at various pictures :-)

Cheers, Robin

|

Hi Robin,

that's an interesting point you raise that could affect other builders so I had a look at the IVA manual. The closest I can find is in Section 3A requirement 10. that says...... 10. The fuel tank must be positioned so that in the event of a leak the fuel could not accumulate or find a path to the passenger compartment. (if fitted in a compartment there must be a drain which does not exit onto a heat source)

However, this is not an issue on the Sabre because the plate you see above that holds filler neck and cap is not sealed to the wing so any spills will just drip to the road below.

The photo below shows the filler neck before the wing was fitted, which I think explains it better.

Fuel Filler Fuel Filler by Sabrebuilder, on Flickr

There is quite a big gap around the filler neck and the wing.

In fact, it was while I was fitting the tether that I realised I need to fit some kind of inner wheel arches to stop rain and road dirt being thrown up by the wheel all over the filler neck.

I think my car will be OK but thanks for the feedback as I'm keen to head off as many IVA issues as possible.

cheers, Peter

|

29th April 2021, 18:39

|

|

Senior Member

Enthusiast

|

|

Join Date: Mar 2005

Posts: 3,079

|

|

Just a small update to show you all what I'm working at the moment when I get the odd spare moment in the garage.

When fitting the tether to the fuel cap I realised that I needed to fit inner wheel arches or all the road muck will go all over the filler. My car wasn't fitted with anything as it was never finished. The Sabre manual says " Cut aluminium splash plates to fit between the body and the wings, behind the rear wheels. Secure to the inner wheelarch with self tapping screws. Fit edge seal to the splash plates where they contact the wings."

But, I thought I'd try and fabricate something a bit more professional looking so I bought these truck mudguards.

They looked about the right size and cost £36 delivered.

My plan was to cut them up to fit.

Rear inner wheel arches Rear inner wheel arches by Sabrebuilder, on Flickr

I first made a cardboard template and set about cutting up a mudguard. I used my jigsaw to cut the edge off and a hand wood saw to cut the slots for the Sabre's body flanges.

Inner rear wheel arch template Inner rear wheel arch template by Sabrebuilder, on Flickr

I then offered it up and with a bit of pushing and shoving it popped in to place. I then discovered the mudguard is the exact same diameter as the Sabre's inner wheel arch. A perfect fit!

Inner rear arch top Inner rear arch top by Sabrebuilder, on Flickr

I then found on-line this edge seal that has a finned edge and I fitted that to the cut edge of the mudguard. It's good stuff but a PTA to fit to the now floppy edge of the mudguard.

Small leaf fin edge seal Small leaf fin edge seal by Sabrebuilder, on Flickr

At the front and top I've fixed the arch in place with m6 rivnuts.

Inner rear wheel arch front Inner rear wheel arch front by Sabrebuilder, on Flickr

But at the back there is nothing to fix the mudguard to and it's too flexible to leave as is, so I am going to make up a bracket to support it that will be fixed behind and to the lower edge of the body tub.

Inner rear arch back Inner rear arch back by Sabrebuilder, on Flickr

It's coming together nicely and looks production.

A bit more to do and the other side, of course.

Stay safe..............peter

|

|

Currently Active Users Viewing This Thread: 2394 (0 members and 2394 guests)

|

|

|

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is Off

|

|

|

All times are GMT +0. The time now is 08:49.

|