|

|

| Dino 246 Builds and Discussion Da da da da daaa daa da da, ohoho Dino |

3rd February 2017, 16:11

|

|

Senior Member

|

|

Join Date: Jun 2009

Location: leicestershire

Posts: 325

|

|

chassis

chassis

Hi

Yes similar. The LB has the struts in a more upright position rather than inclined inwards as on the mgf.

I've started on mounting my focus rs box to my spare cosworth v6. I've upended the v6 engine and machined a spigot bearing that fits in to the v6 crankshaft. I will now bore this to fit the input shaft on the focus box thus centring it ready to mark out my adaptor plate.

Ian

|

4th February 2017, 17:36

|

|

Senior Member

|

|

Join Date: Jun 2009

Location: leicestershire

Posts: 325

|

|

chassis

chassis

Hi

I've turned the other end of the spigot jig and fitted to the gearbox. I now need to mate the two together and start on the adaptor plate.

ian

|

8th February 2017, 08:03

|

|

Senior Member

|

|

Join Date: Jun 2009

Location: leicestershire

Posts: 325

|

|

chassis

chassis

hi

With the jig pressed into the end of the V6's crank I've lowered the M66 gearbox via the splined input shaft onto the engine. this will centralise engine and gearbox.Looks like everything will work. Now on to plot the mounting holes for the adaptor plate. I have the bolt pattern for the v6 block but I can't find the bolt pattern sizes for the Volvo/Ford M66 box anywhere. Anyone have any idea's?

Ian

|

19th February 2017, 14:26

|

|

Senior Member

|

|

Join Date: Jun 2009

Location: leicestershire

Posts: 325

|

|

chassis

chassis

Hi all

Does anyone who reads this know much about the Vw/audi 02m 6 speed box?

As fitted to the RS3 and cupra.

Been told these can handle more power than the ford focus st/rs box and they are easier to get hold of. Plus spares and LSD's are much cheaper.

I also like that the starter is bolted through the gearbox rather than from the engine side.And it's cable operated like the ford box too.

ian  |

21st February 2017, 04:37

|

|

Senior Member

Enthusiast

|

|

Join Date: Mar 2008

Posts: 225

|

|

Re-reading this I remembered that Hondas of the 80s and 90s used to have very low bonnet lines - and so shorter strut (or wishbone/strut) front suspensions. Nowadays cars have higher bonnet lines to add a couple of inches of crumple for the poor pedestrians who get hit.

I'm no suspension expert but you do get the geometry by drawing a line from the top of the strut and intersecting it with the line created by the bottom wishbone. So I guess just shortening the strut would have an effect on geometry.

|

23rd February 2017, 09:03

|

|

Senior Member

|

|

Join Date: Jun 2009

Location: leicestershire

Posts: 325

|

|

chassis

chassis

Hi

I've seen this diagram before. I would guess if the strut is shortened along the same radius it would still be ok? Looking at the photos I've attached LB's struts look almost vertical.

Ian

|

25th February 2017, 02:11

|

|

Senior Member

Enthusiast

|

|

Join Date: Mar 2008

Posts: 225

|

|

shortening struts

shortening struts

If you take 2" off this strut and redraw the diagram you can see a big change in the roll centre height and the virtual reaction point.

|

25th February 2017, 10:25

|

|

Senior Member

|

|

Join Date: Jun 2009

Location: leicestershire

Posts: 325

|

|

chassis

chassis

Hi

You're showing a drawing here of the front suspension. I'm going to copy the front suspension from my deon and it will be the same just new hub carriers.

It's the rear suspension I'm looking at altering. I know that just loping of 2" off will alter the swing radius as you say,this is must be why the LB struts are more upright.To Keep the virtual radius with a shorter strut the same moving the top mounting point out then will surely bring it back in line?

I'm hoping to get my adaptor plate cnc'd either this/next week and will start by building the engine cradle/suspension. I want to keep as close to the deon as possible.

Ian

|

26th February 2017, 00:50

|

|

Senior Member

Enthusiast

|

|

Join Date: Mar 2008

Posts: 225

|

|

Hi, by the way - please take my comments about engineering and suspension with a pinch of salt! I don't pretend to know much about either. If you want knowledgable feedback and people aren't answering on here then maybe posting some questions on the middy section of the locust site would get you useful responses. I'm following the discussion with interest.

cheers

Ross

|

11th March 2017, 00:22

|

|

Senior Member

Enthusiast

|

|

Join Date: Mar 2008

Posts: 225

|

|

Have you seen Bloozebury's Canadian project? He is modifying a Fiero, widening, lowering, changing suspension geometry, fitting a transverse V8. There are many drawings, including a rear suspension that was originally strut and has been considerably altered. His website is: http://bloozeown.weebly.com/

and there's even more detail on the Dutch Fiero site : http://www.fiero.nl/forum/Forum3/HTML/000116.html |

14th March 2017, 10:03

|

|

Senior Member

|

|

Join Date: Jun 2009

Location: leicestershire

Posts: 325

|

|

chassis

chassis

Hi all

Right-does anyone have an accurate set of dimensions for a Dino 246? I have a couple of sets of measurements from searching through my huge collections of dino books, and then several from the internet, that although similar are not the same!!! I'm after wheelbase, front track and rear track please. Or if anyone can point me in the right direction!! cheers

ian

|

14th March 2017, 10:55

|

|

Senior Member

|

|

Join Date: Jun 2009

Location: leicestershire

Posts: 325

|

|

chassis

chassis

hi all

update--

just for reference I have - taken from the anthony curtis Ferrari Dino book which seems to be a definitive book on the dino written around 1990-

wheelbase 2343 mm (7 foot 8.25 inches)

front track 1416 mm (4 foot 7.75 inches)

rear track 1441 mm (4 foot 8.75 inches)

these tally (within 2/3 mm I guess from rounding up/down) with several other books on the dino. But I do have another book with a set giving a wider track? Could this be from the "chairs and flairs" car? or was it just wider tyres and flared wheel arches. The internet search gives varied dimensions so I've taken them as not to be an accurate account due to armchair writers giving their take on the car!!

cheers Ian

|

14th March 2017, 19:09

|

|

Senior Member

|

|

Join Date: Sep 2011

Location: Teesdale

Posts: 238

|

|

Hi Ian

I have a Brooklands "road test" book for the Dino which is basically a compilation of magazine road tests for the car.

There do seem to be several different figures quoted in the different articles but the consensus seems to agree with those quoted in the "Motor" road test No 30/71 which gives

Wheelbase 7' 8¼"

Front track 4' 7¾"

Rear track 4' 8¾"

I'm inclined to believe the above figures as the magazine article has gone to the trouble of detailing a lot of the car's facts and figures including such esoteric facts as the King pin inclination angle (9° 3’ in case you are interested lol)

Neil

|

15th March 2017, 00:46

|

|

Senior Member

Enthusiast

|

|

Join Date: Mar 2008

Posts: 225

|

|

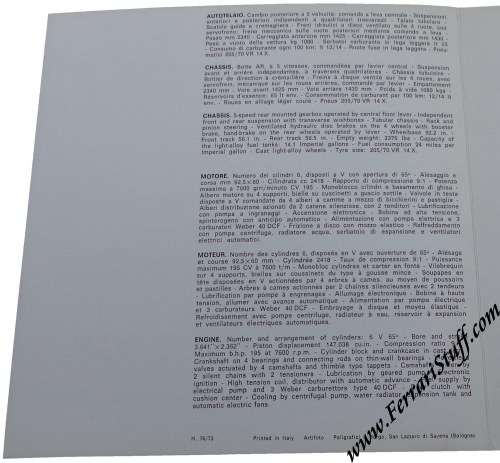

Hi, the official factory 246GT manual lists:

1425mm the front track (carreggiata a terra)

1430mm the rear track (carreggiata a terra)

my Italian is pretty basic but I think this is the measurement from vehicle centre to centre of wheel AT GROUND LEVEL.

The Ferrari brochure lists it as:

wheel base 92.2" in English (2340mm in French)

front track 56.1" (1425mm)

rear track 56.5" (1430mm)

The 206 GT is listed at rear=1400mm by the way. And the 'chairs 'n flares' would only have a different track if it had different offset - otherwise the centre of the wheel would be in the same place.

cheers

Ross in NZ |

15th March 2017, 01:02

|

|

Senior Member

Enthusiast

|

|

Join Date: Mar 2008

Posts: 225

|

|

Ferrari would probably have measured in mm so the Imperial measurements are just approximate translations. I reckon the Factory manual and brochure are the best bet:

wb 2340mm

ft 1425mm

rt 1430mm

cheers

Ross in NZ

|

29th March 2017, 20:56

|

|

Senior Member

Enthusiast

|

|

Join Date: Mar 2008

Posts: 225

|

|

There is a part finished Minotaur kit on EBay at present. It comes with a link to lots of chassis and detail pictures. The chassis looks a bit heavy with 50x50mm box section (?). 6 litre Chev and Porsche 'box. This is what 10 years and 30,000GBP of parts gets you!

https://www.amazon.co.uk/clouddrive/...are_link_email |

15th April 2017, 10:03

|

|

Senior Member

|

|

Join Date: Jun 2009

Location: leicestershire

Posts: 325

|

|

chassis

chassis

Hi all

My adaptor plate has finally arrived and been offered up to the cosworth V6.

After looking at several options for a suitable gearbox I've decided to go with a E53 gearbox from a mark 2 toyota mr2 turbo. Some of the turbo guys run upwards of 400bhp!! Now these are getting quite rare and when the do come up they are snapped up within minutes or are quite pricey still requiring a rebuild. So my next option was a complete car.

Well after searching for a few weeks a suitable donor car appeared and the deal done. Low 89,000 Kilometer jap import car (not miles) dry stored for the last 4 years. I'm not a big fan of stripping rare cars that should really be put back on the road but I will sell on what I don't need-everything else apart from the gearbox/drive and intermediate shafts/starter motor/flywheel/clutch and gear selector with all cables.

Ian |

16th April 2017, 15:32

|

|

Member

|

|

Join Date: Apr 2015

Location: Sydney Aust

Posts: 72

|

|

I had a bit of a look through the posts and I have built suspension from scratch.

This will give you some rules of thumb that may give you a guide or confuse you more.

My approach.

Start with the wheel offset that you want for the car that you are building.

The upright ,disk and caliper has to fit inside the chosen offset.

Once you place this on the ground you then know how long the arms need to be.

Scrub radius.

A line through the top ball joint passing through the lower ball makes contact at a point on the road.

This is part of an angle called KPI

With the wheel fitted it will land somewhere on the inside of the Tyre patch, this is the scrub radius ,zero SR is the centre of the tire this will make the car very vague at high speed, front wheel drives generally have a low SR as it cancels out torque steer but not good on RWD, I would not go any less than about 60mm inside the CL off the tire.

If you have to much ,lets say it lands not under the tire contact patch but inside that it will give heavy steering and high feed back on the wheel if you get ruts on pot holes on the road.

SR helps with self centring which is very handy if the car steps out you can just let go of the st wheel and the wheels will self centre then you just regrab the wheel and you are back in control.

The lower arm height location is all about the upright lower ball joint height of the road.

You need to have the lower arm running slightly uphill to the chassis pick up point.

This will help control the roll centre movement across the car and also in the vertical position when the car dives and turns in.

A car that has poor RC control is unpredictable, EG All the weight above the RC applies a load onto the tyre, the higher the RC the less load applied.

The lower the RC the more load because you have more weight above the RC.

If a car if cornering and it has X RC then you get on it harder and the RC changes dramatically then the attitude of the car can change sometimes for the worse.

The upper arm needs to run down hill from the upright to the chassis, changing the angle will change the RC height I have found on rear eng cars it likes to be lower say at about 60-30mm of the ground.

Reason being you have less weight over the front (no eng) so you use RC to get tire loading.

Steering arm.

I like a bolt on steering arm as it gives you a better chance of getting the bump steer correct.

Steering rack location.

If it’s a front steer you need to be careful that you can get a reasonable ackerman.

On rear eng cars I always run anti ackerman meaning it has neg toe out on turn because no weight in the front the front inside tire goes into slip very early so having less to out on turn will give more grip on entry but makes no difference after apexing.

Also having the rack forward of the steering arms on a front steer will give the same effect.

Upright

What ever you choose you need to know the KPI if it has 6 deg that is about the caster you will run as a starting point.

Knowing this will give you a point to start on upper arm length and setback for the upper ball joint.

Rear roll centre

Very important on a rear eng car as they generally have to much rear grip because of the weight on the back tire.

This will generally cause under steer issues because the rear just keeps overpowering the front tires.

To sort this you raise the rear RC and reduce the grip and it balances the car and allows you to get on the power early and get it to sit on the back tire at point of entry.

Hope this helps you make decisions on set up or what components to pick.

Bit hard to change RC on struts from memory ,probably easier to adjust the lower inner up or down.

One thing I have seen done and it was smart was a strut leg was cut down and a fitting welded in that had a 5/8 thread in it to accept a rose joint that was fitted in the upper arm, so the leg was turned into an upright.

That arm in your pics made to take a r/joint as a ball joint is fine but you cant do that on the loaded arm ( the one with the spring/shock attached) say the lower you cant use that idea it will break eventually, I know this because I have done it and it did break at 23.000km road and track miles.

Any r/joint if in single shear (upper lower b/joint, outer tie rod on steering arm) should have a washer larger than the joint so as it is still captive if the joint fails.

Jim

Last edited by ozi jim; 18th April 2017 at 08:59..

|

18th April 2017, 03:43

|

|

Senior Member

Enthusiast

|

|

Join Date: Mar 2008

Posts: 225

|

|

Once again your down-to-earth engineering knowledge amazes Jim. Thanks.

|

20th April 2017, 23:34

|

|

Senior Member

Enthusiast

|

|

Join Date: Mar 2008

Posts: 225

|

|

This thread has some very in-depth engineering and description of the suspension requirements. Unfortunately it is also pretty dense and takes a long time to digest. Someone might find it useful:

http://reversetrike.proboards.com/thread/343 |

|

Currently Active Users Viewing This Thread: 1 (0 members and 1 guests)

|

|

|

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is Off

|

|

|

All times are GMT +0. The time now is 03:12.

|